One of the key challenges in structural health monitoring (SHM) for aerospace and other high-performance sectors is the early detection of internal damage in composite materials without compromising their mechanical integrity. As part of its contribution to the INFINITE project, the University of Sheffield Advanced Manufacturing Research Centre (AMRC) has recently published a case study demonstrating a major advancement in this field.

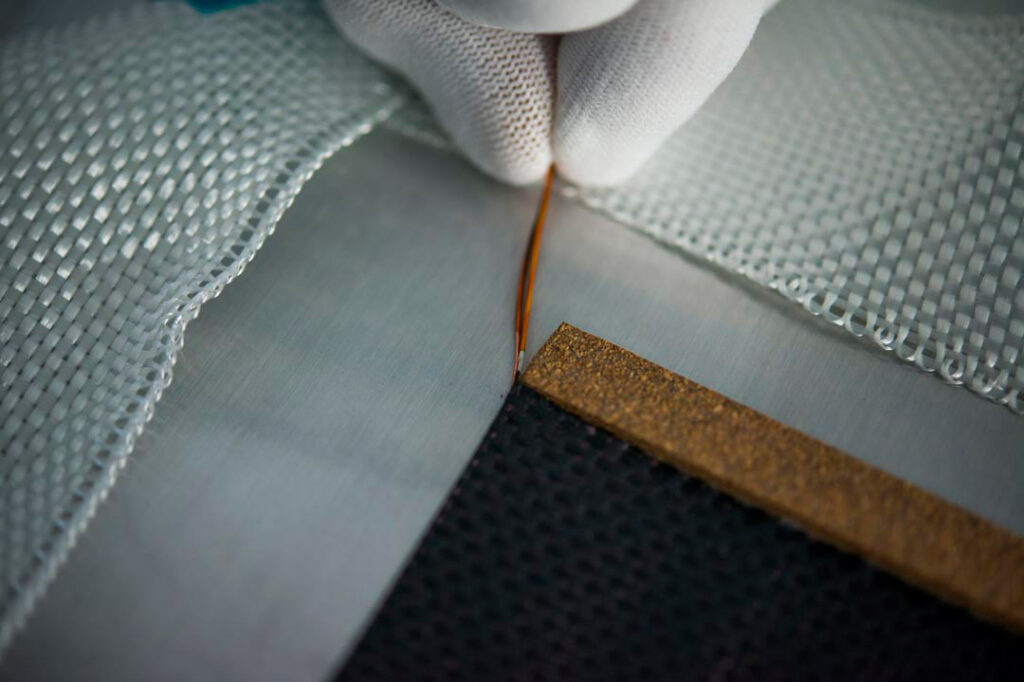

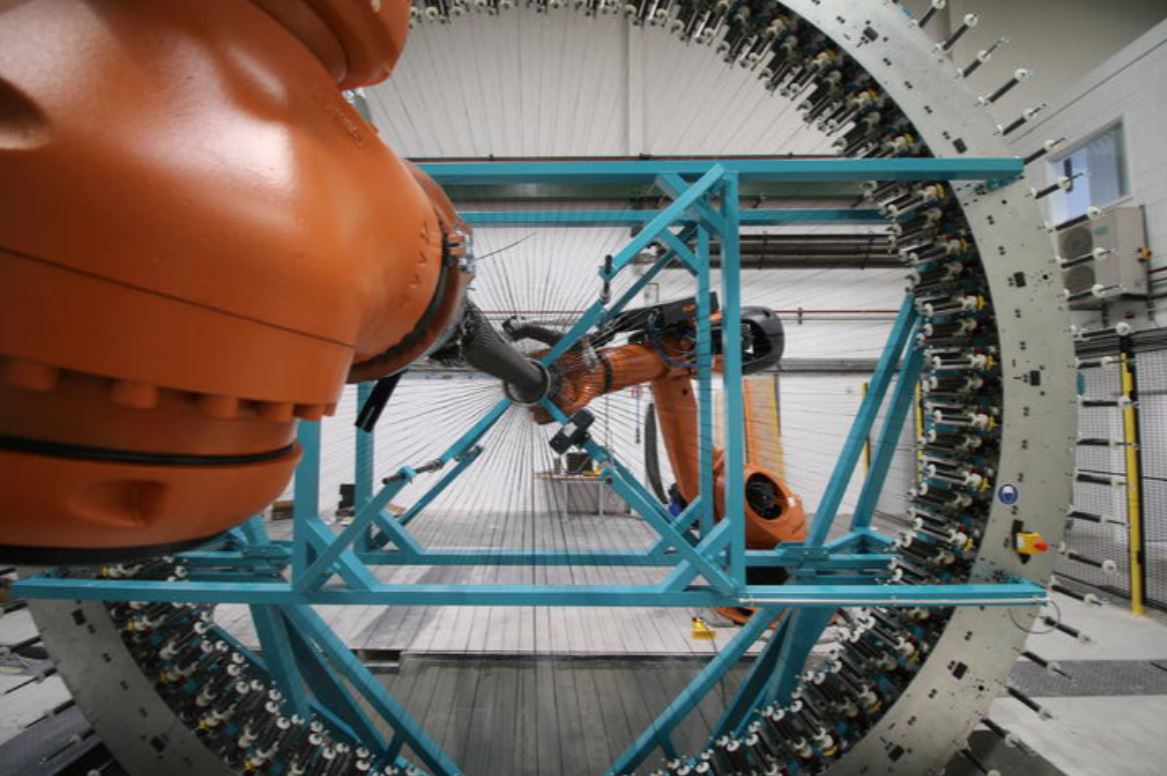

The study, conducted with support from the High Value Manufacturing Catapult, explored new methods to improve the integration of optical fibres and magnetic microwires within braided composite structures, enhancing the robustness and reliability of embedded sensing systems. This work builds on AMRC’s previous expertise in integrating sensors into composites and aligns directly with INFINITE’s goal of enabling wireless, real-time monitoring of aircraft structures across their lifecycle.

The microwires, developed by INFINITE partners UPV/EHU and Tamag Iberica SL, and the data acquisition system provided by RISE Research Institutes of Sweden, played a crucial role in enabling advanced stress and damage detection capabilities during the trials.

Smart integration and testing

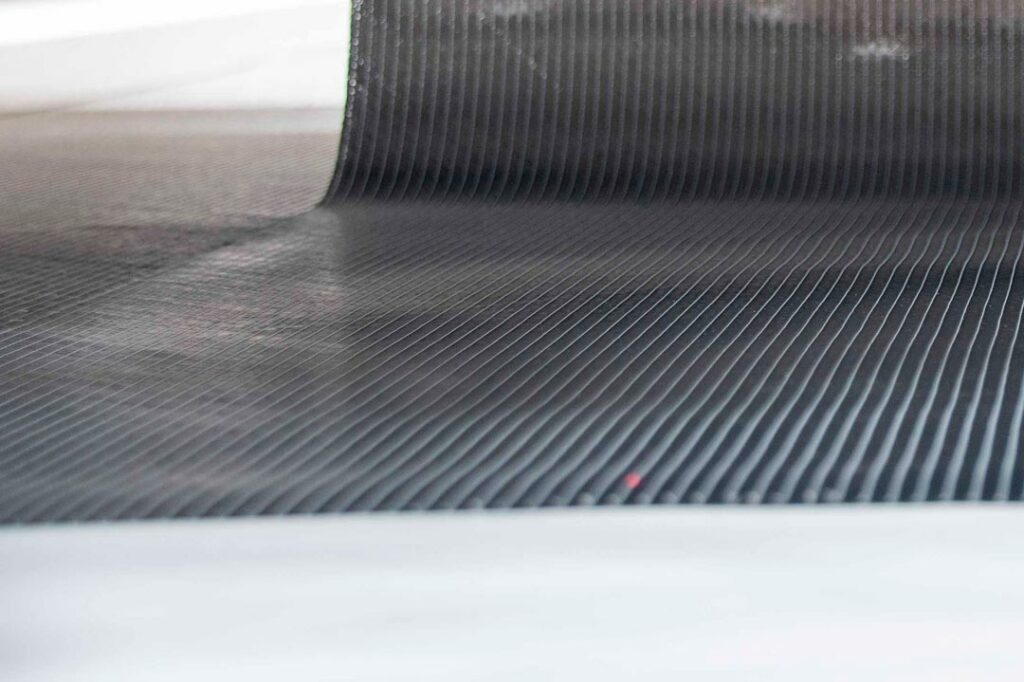

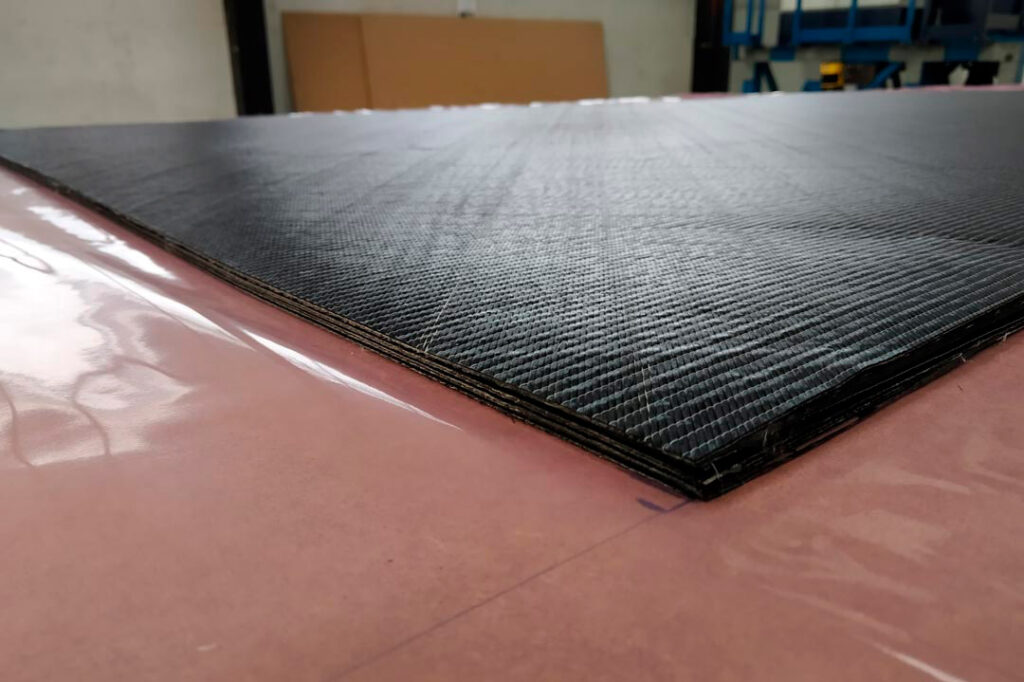

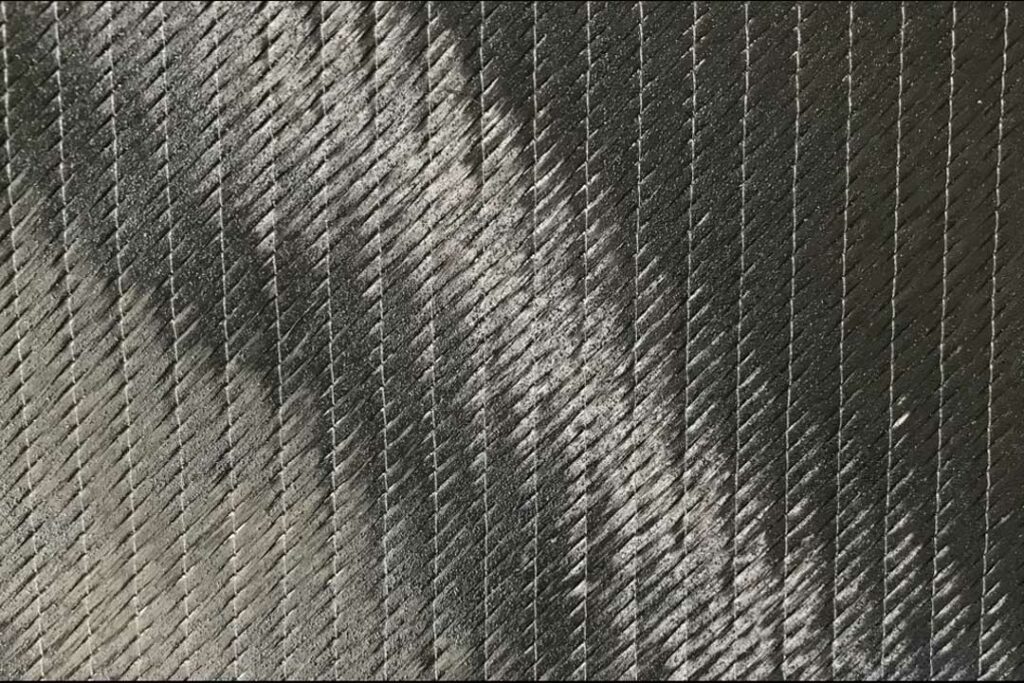

AMRC embedded sixteen microwires into biaxial and triaxial braided preforms and monitored their behaviour throughout resin infusion, curing and mechanical testing. By experimenting with different placement depths within six-ply composite panels, the team was able to identify the optimal location for sensor performance.

Tests revealed that placing microwires in the third layer of the laminate offered the best balance between signal strength and durability, outperforming placements nearer the surface (more prone to damage) or deeper layers (where signals weakened).

A step forward in smart composite materials

This research represents a significant step forward in SHM for braided carbon fibre composites, addressing long-standing limitations in detecting internal failures like matrix cracking or delamination. The improved sensor placement strategy demonstrated by AMRC:

- Increases sensitivity to material deformation.

- Enhances signal stability during stress testing.

- Lays the foundation for non-destructive evaluation techniques applicable to aerospace, automotive and civil engineering.

Synergies with the INFINITE project

The insights and methodologies developed in this study directly support the objectives of the EU-funded INFINITE project, which seeks to create sensorised composite materials capable of monitoring their condition from manufacturing to end-of-life. The collaboration between AMRC and other INFINITE partners exemplifies how European R&D synergies are driving innovation in smart materials and sustainable aerospace solutions.

🔗 For more on the case study, visit this or explore the results through INFINITE’s communication channels.