On July 16th, the INFINITE project consortium gathered in Brussels to celebrate its Final Review Meeting, marking the end of an exciting journey of European collaboration, research, and innovation in the field of aerospace composite manufacturing and smart monitoring.

During the session, the consortium partners presented the project’s key outcomes to Georgios Bampanis, Project Officer from the European Commission, whose insightful feedback will help guide the next steps in building upon the achievements of INFINITE.

While the main session took place in person in Brussels, several partners also joined online, ensuring full participation and engagement from the entire consortium—just as it has been throughout the project.

Highlights and Key Achievements

Each Work Package leader presented their major accomplishments, followed by a successful demonstration of INFINITE technologies, showcasing their technical maturity and potential for real-world impact. Some of the most significant outcomes include:

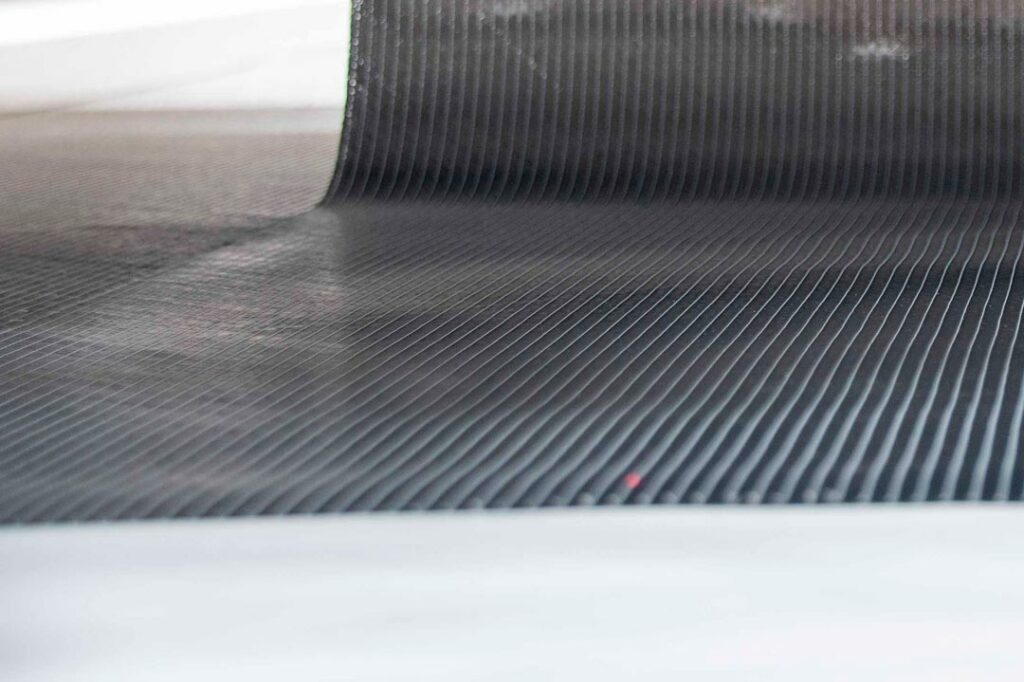

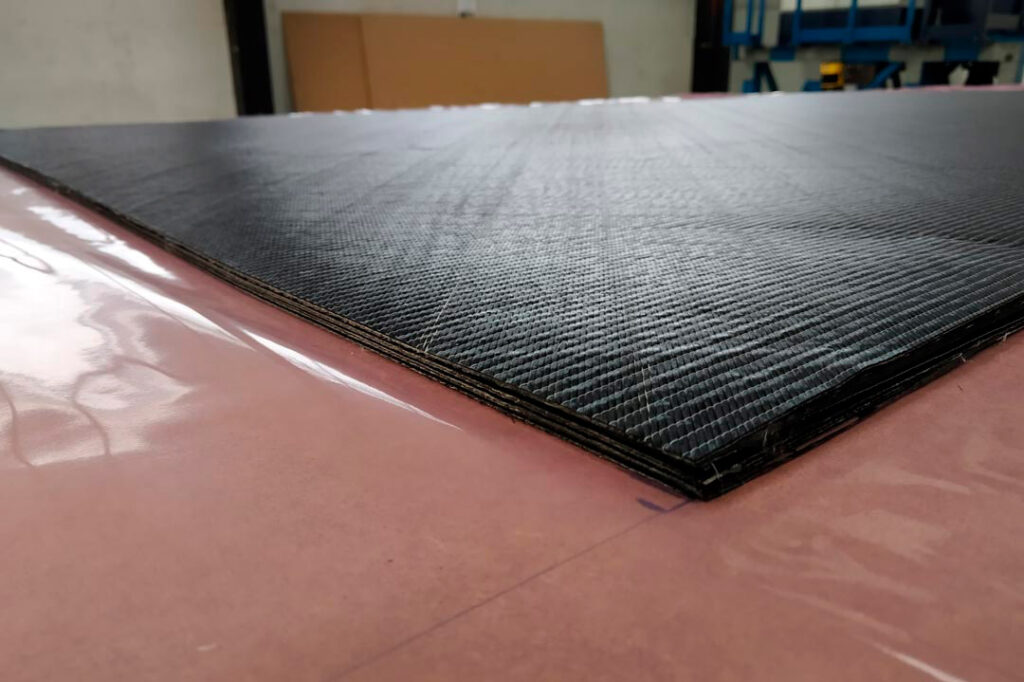

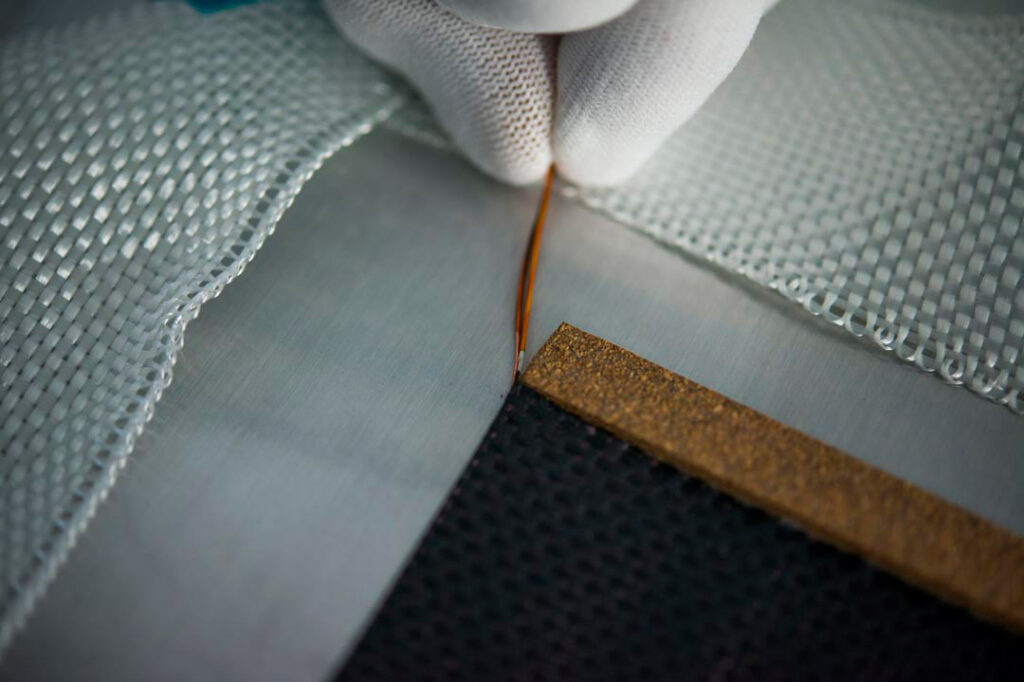

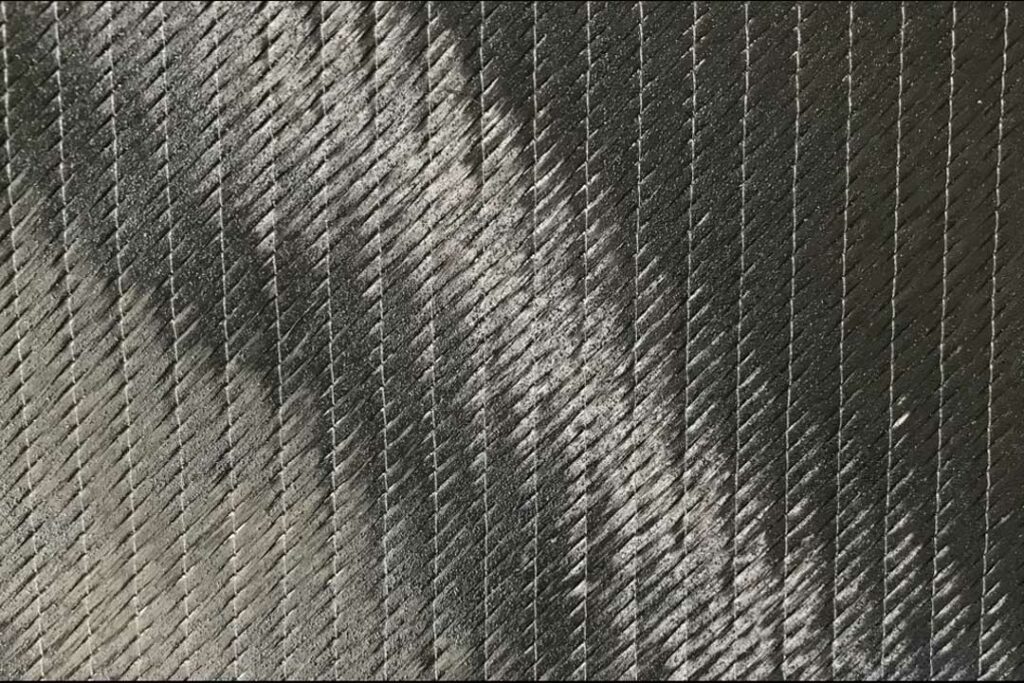

- The development of ferromagnetic microwire-based sensors seamlessly embedded into composite structures, enabling real-time monitoring throughout the full lifecycle of a component—from manufacturing to service and end-of-life.

- A portable, low-frequency reader and a validated wireless sensing system, capable of capturing data during composite production processes.

- A robust Structural Health Monitoring (SHM) algorithm for damage detection, localization, and quantification, supporting predictive maintenance.

- A specialized repair toolkit and methodology for non-crimp fabric (NCF) structures, informed by sensor data.

- A lifecycle data dashboard and Material Passports for enhanced traceability and digital continuity.

- Circular strategies including recyclability of materials and microwires, along with full Life Cycle Assessment (LCA) and Life Cycle Costing (LCC) analyses.

INFINITE has reached a Technology Readiness Level (TRL) of 3–4, laying the foundation for further developments and cross-sector applications in aerospace, automotive, and renewable energy.

A Project Built on Innovation—and Human Connections

Over the past three years, we’ve worked together to advance aerospace composite manufacturing and smart monitoring solutions — tackling technical challenges, pushing technological boundaries, and building strong collaborative relationships across Europe.

As Peio Olaskoaga, Project Coordinator from IDEKO, reflects:

“We’ve shared work meetings, technical reviews, international fairs… and also dinners, beers, and great conversations that brought us even closer as a team. That human side is what truly makes a project like INFINITE a success.”

What’s Next?

INFINITE closes its chapter as a project, but its innovations open the door to a more connected, sustainable, and intelligent future for advanced composite manufacturing. Some key activities for that are:

- Industrial pilot programs to validate long-term performance.

- Engagement with early adopters in aerospace and beyond.

- IPR strategies to protect innovations and support commercialization.

- Alignment with certification standards for broader market entry.

- Continued collaboration and funding to scale up solutions.

Learn more: https://www.infinite-project.eu